What a Leaking Hatch does to the Equipment Beneath It

The heating system on our Prout Escale was a running joke in the family. Prout Catamarans had installed a Espar/Eberspúcher DL-4C diesel furnace in the back of the boat. Its location was in the hollow space that connected the two rear crash compartments under the traveler of the mainsail. Unfortunately, the hatch over it encouraged regular drenchings whenever the hatch surface got wet.

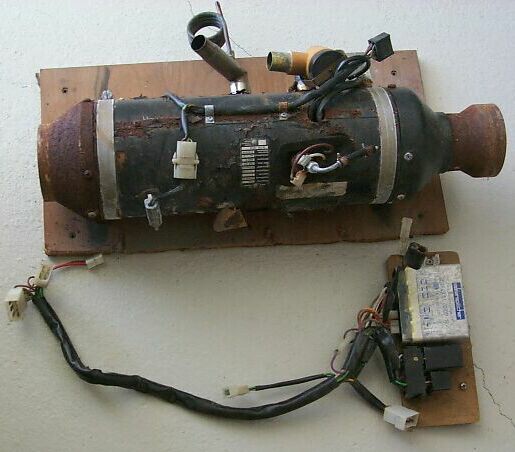

The results were predictable, as the unit lasted for about two years before collapsing in a pile of rust. All exterior surfaces are rusting due to the constant water ingress through the leaky hatch. Luckily, the electronics locked the unit out before its failure could harm us.

What was left of the OEM furnace after two years in service.

Espar units for marine use feature stainless heat exchangers, etc. although I am not convinced that any furnace currently sold could have survived the conditions that existed under the heater hatch. Since the hatch over this heater and the other hatches were leaking water into the rear compartment so that standing water was normal and expected, the humidity in the compartment must have approached 100% on near constant basis all summer long.

More worrisome are the indications on the Prout Escale master plans, indicating that Prout Catamarans usually installed the hydraulic steering ram under this hatch. While Prout Catamarans has at best a chequered history of actually building to plan (see the sections on misplaced hatches, electrical issues, etc.) I urge any Escale owners who have a hatch behind the mainsail traveler to open it and have a look. Inspect your steering system!

Not to have heat in Maine is a major inconvenience. To lack steering is a much more serious problem. Remember, Murphy's Law dictates that things always break at the most inopportune times.

Best Estimate of Time Required:

| Removal of OEM Espar unit, disconnect wiring, plug diesel line | 1 hour |

|---|---|

| Research heater manufacturers, compare specifications, select vendor | 8 hours |

| Review reports detailing installations, study manual | 3 hours |

| Take stock of what could be reused, what would need to be replaced | 1 hour |

| Order unit, required auxiliary parts such as relay board, Cu tubing, etc. | 1 hour |

| Total | 14 hours |

|---|