Keeping the Fuel System Clean

Here is a partial view of the diesel tank in our Prout Escale and the

four lines that penetrate it. From left to right: Tank tender, diesel

return from engine, diesel to engine, diesel furnace.

Here is a partial view of the diesel tank in our Prout Escale and the

four lines that penetrate it. From left to right: Tank tender, diesel

return from engine, diesel to engine, diesel furnace.

The tank-tender (a level sensor) for the diesel tank didn't work properly until we discovered all the built-in kinks in the line and removed them. The lines running to the water tanks had fewer corners to snake around, so they tended to kink less.

The return line carries unused diesel back from the engine. The diesel intake now runs to a RACOR filter mounted in this compartment instead of the engine compartment where Prout had installed the OEM Lucas unit.

Not only does the RACOR unit incorporate a priming pump, it also offers much easier access to the filter elements - the Lucas unit was mounted so out of the way that access was only for the very limber and long-armed. We replace the primary and secondary filter elements every year, even though the engine only runs less than a hundred hours on each one.

The single line that carries fuel to the diesel furnace is a 3/16" OD copper line that we installed when we discovered that Prout Catamarans had used plastic when they installed the old Espar furnace. Note how the first three terminals were welded into the tank, while the third consists of a screw-on terminal not meant for marine installations (i.e. it's not made of stainless and rusting). The bulkhead at the bottom of the page separates the engine and diesel compartments.

We have been thinking hard about our Diesel tank options since the 28 gallon diesel tank installed by Prout Catamarans is totally inadequate for anything but coastal sailing. Given our thirsty engine, it runs dry rather quickly. We plant to retrofit larger tanks in the rear crash compartments where they would help counteract the constant list of our Prout Escale while at anchor without the dinghy.

Besides retrofitting "reserve" tanks, we also had to replace the diesel

delivery and return infrastructure installed by Prout Catamarans. I have

never been a great fan of fixed copper pipe in boat installations. Our

pipes were soldered together with lead and were degraded quickly. Fuel

hose is more flexible, can be installed in one seamless piece, and will

not degrade as quickly as copper (particularly if you use the gasoline-grade

hose in a diesel installation).

So while we fixed the diesel intake line when we installed the Racor filter, we waited with replacing the diesel return line until we pulled the engine for maintenance. This was a big mistake since we would have discovered another classic Prout Catamarans construction "feature".

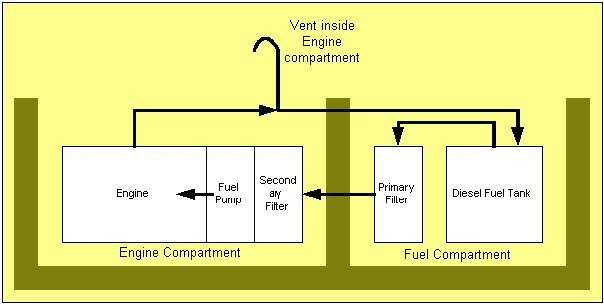

The return line carries the portion of unused but pressurized (and

hot!) diesel back to the tank that the engine did not use. Prout Catamarans

opted to incorporate the vent for the diesel tank INTO

THIS LINE. Never mind that the line is pressurized and that any loss

in height of the line would cause LOTS of HOT diesel to be pumped directly

into the engine compartment! Diesel may have a fairly high ignition

temperature but this still does not excuse the hair-raising installation

we have witnessed on our Prout Escale. Furthermore, the US Coast Guard

does not care if a construction failure made your boat pollute the ocean

- the fine is yours to pay.

We discovered the vent the hard way when it dropped 1" below installation

height during engine maintenance. Luckily, since the engine hatch was

open, we noticed the spilled diesel quite quickly - but the soundproofing

in the engine compartment had already absorbed a good amount of diesel

which had to be painstakingly squeezed out of it.We replaced the copper

return line with a rubber one and are currently evaluating better fuel

tank venting options. Is it me or is it strange to vent a fuel tank

into the engine compartment instead of venting it externally?

Our

current diesel tank now has a rubber return line, and the proper tube

and filter for the diesel furnace. Last but not least, we installed a

pull-handle into the hatch for the diesel compartment. It makes accessing

this area much easier.

Our

current diesel tank now has a rubber return line, and the proper tube

and filter for the diesel furnace. Last but not least, we installed a

pull-handle into the hatch for the diesel compartment. It makes accessing

this area much easier.

Such a handle is water-proof when installed properly, so there is no

good reason not to install one in hatch surfaces that otherwise risk

fingernails to be opened.

Best Estimate for Time Required:

| Remove old filter mounting, re-plumb hosing | 1 hour |

|---|---|

| Install RACOR unit, bleed Diesel system | 1 hour |

| Install Copper Line for Furnace System | 2 hours |

| Discover brain-dead vent installation | 2 minutes |

| Squeeze Diesel out of Soundproofing | 1 hour |

| Retrofit proper vent hose | 2 hours |

| Repair built-in kink in tank tender unit | 1 hour |

| Total | 10 hours |

|---|